UC Berkeley team develops AI framework for defect-tolerant metamaterials in manufacturing

GraphMetaMat system aims to bridge design and manufacturing for high-performance materials.

A University of California, Berkeley led research team has created an artificial intelligence framework to design 3D truss metamaterials that can maintain performance even when manufacturing defects occur.

The patent-pending system, called GraphMetaMat, is detailed in the July 22 cover story of Nature Machine Intelligence.

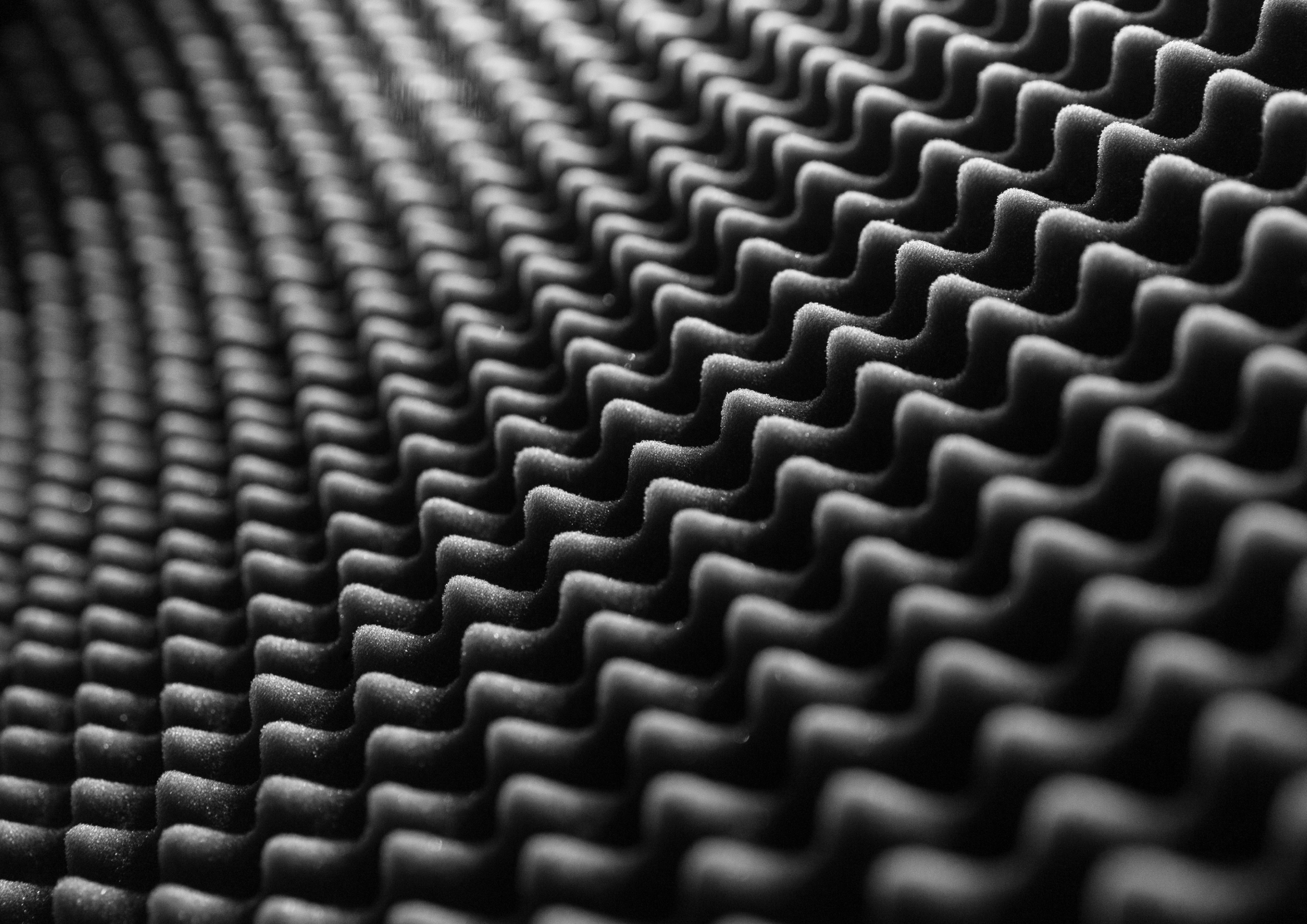

Metamaterials are engineered structures with properties not typically found in natural materials. They are used in applications such as aerospace panels, automotive components, and soundproofing systems. UC Berkeley says GraphMetaMat can produce designs tailored to specific manufacturing methods, such as 3D printing, while integrating engineering constraints that address fabrication-induced imperfections.

Addressing limitations in current design approaches

Xiaoyu (Rayne) Zheng, associate professor of materials science and engineering and principal investigator on the study, says the approach differs from existing methods, which often focus on ideal, defect-free conditions.

“GraphMetaMat shows that AI can give you a realistic design tailored for a specific manufacturing method, like 3D printing, and optimized to withstand various manufacturing related defects,” says Zheng. “It sets the stage for the automatic design of manufacturable, defect-tolerant materials with on-demand functionalities.”

The researchers note that traditional design techniques such as topology optimization can handle basic performance metrics, like elasticity, but often fall short when capturing complex nonlinear behaviors needed for energy absorption or vibration mitigation. Existing AI applications in the field have been constrained by limited training data, particularly when using graph neural networks.

How GraphMetaMat works

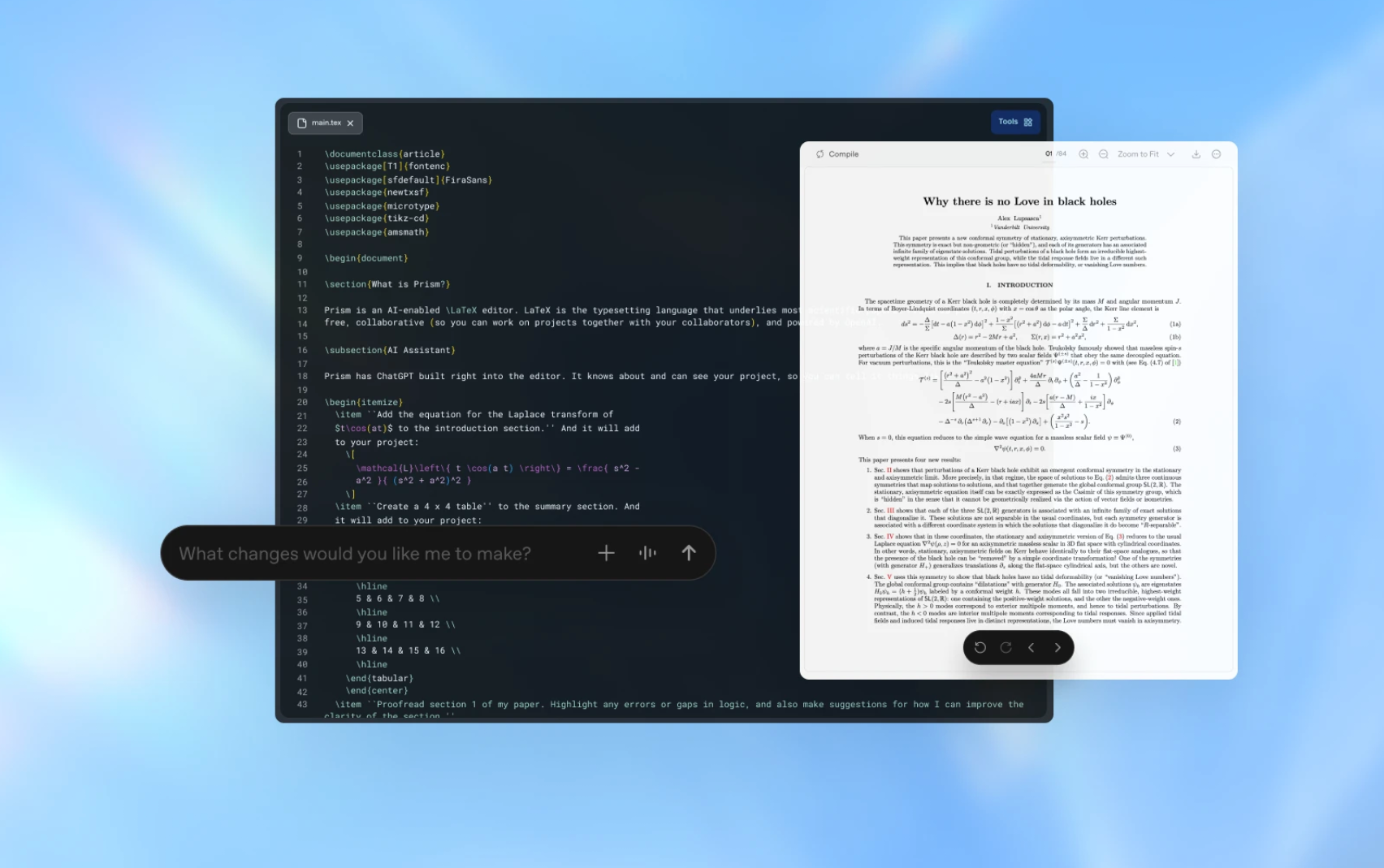

To address the data gap, the team combined reinforcement learning, imitation learning, a surrogate model, and Monte Carlo tree search into the GraphMetaMat system. Users can input specific performance requirements, such as a target stress–strain curve or vibration attenuation parameters, and the AI generates a material design by iteratively building its geometry and topology.

Marco Maurizi, postdoctoral researcher in the Department of Materials Science and Engineering and lead author of the study, says, “Users can create metamaterial designs, represented as graphs, entirely from scratch based on custom inputs — such as a desired stress–strain curve or specific vibration attenuation gaps where mechanical waves are blocked at certain frequencies. Our AI system then iteratively adds graph nodes and edges to define the material’s geometry and topology.”

In testing, GraphMetaMat was used to design lightweight truss metamaterials optimized for energy absorption and vibration mitigation across different frequencies. According to the team, the generated materials consistently outperformed polymeric foams and phononic crystals in these scenarios.

Zheng ADDS, “GraphMetaMat has the unique ability to account for fabrication-induced imperfections. This innovation is a game-changer because it ensures that the generated metamaterials will not fail if they develop a small defect during manufacturing.”